Minienvironment as local purity solution

Large, high-quality cleanrooms are often planned to create permanently clean production conditions. The purchase of a cleanroom generates...

To achieve a high product quality clean conditions play a more and more important role for laser applications.

Cleanroom technology is various products and services. It's not a must to use a cleanroom in production. Because of the etymology the word "room" is the focal point of cleanroom technology. This in turn leaves a lot of companies trusting in classic cleanroom solutions for clean products and process environment. However, an important factor is constantly neglected: Consideration of one's own processes in context with the whole process chain beforehand.

Mostly some processes need a higher cleanliness and not all of the processes have to be banned into a cleanroom, which is an unfavorable option for investment and operating costs.

The air purity for a laser application is not only important for the number of particles in the air or on surfaces, but also for the composition of the particles (material) and the cleanliness of air in consideration of molecular contamination (ACC - Airborne Chemical Contamination).

All components, machines and device components should be electrostatically conductive, to reduce the influence of electrostatic discharges or influences. Suitable parts have to be chosen for the cleanroom solution.

The needed laser protection is realised according to class. Two points have to be considered when a higher laser safety class is needed:

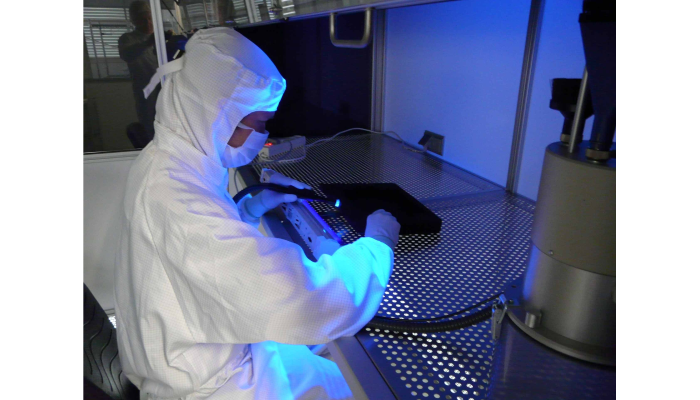

Laser protection foil is often used to separate laser areas. However, this has a decisive disadvantage: laser protection foils do not offer 100% protection against laser radiation, as it cannot be guaranteed that these foils completely separate laser areas from their surroundings, as the picture clearly shows. If it is also a laser area that is subjected to a cleanliness regime, these foils must also be subjected to regular cleaning. It should be noted here that films are difficult to clean as they evade the cleaning wipe due to their flexibility, making a perfect cleaning result rather unlikely.

Laser protection films do not always offer sufficient protection.

If the laser area is subject to a cleanliness regime, the foils have to be cleaned regularly. A sufficiently clean result is hard to achieve, as the flexible foils tend to avoid the cleaning cloth slightly.

We will be happy to support you. Simply click on the button below and send us a non-binding enquiry.

Large, high-quality cleanrooms are often planned to create permanently clean production conditions. The purchase of a cleanroom generates...

To ensure that the cleanroom can keep its air cleanliness class according to ISO, it is necessary to check all factors in the cleanroom for their...

As interest in cleanroom technology grew across countries and industries, the need for a uniform definition of cleanroom standards and norms also...