Semiconductor Industry

Cleanroom and Clenaliness Technology in Semiconductor Industry

The structures in the semiconductor industry are becoming smaller and smaller, whereas the number of processing steps is constantly increasing. In some cases, only 1-10 particles with a diameter of 0.1-0.2 µm are permitted in 1 m³ of air. For a gigabit chip, on the other hand, the number of processing steps has increased to approx. 700. Zero-defect production in all processes has therefore become an indispensable requirement in order to achieve an acceptable production yield.

Make a non-binding enquiry

Avoid contamination effectively

Contamination can have different origins (see diagram). These must be avoided as far as possible.

Historical review - what was the origin and how is it today?

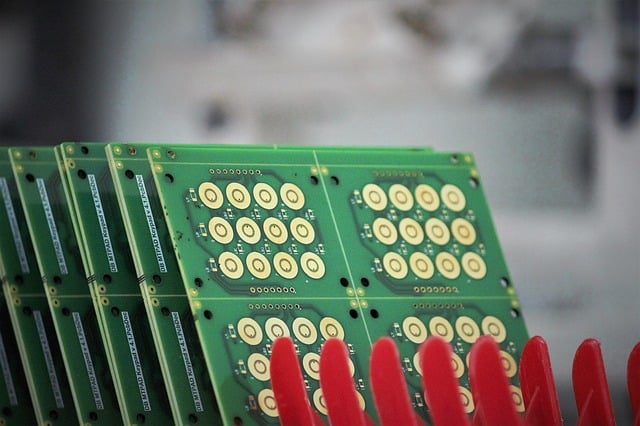

The first introduction of the SMIF (Standard Mechanical Interface) system in the 1980s was a major step towards fab automation. The design was based on a low volume box designed for the storage and transport of silicon wafers in a clean, static environment. Adaptation to the existing semiconductor production and existing machines was required. The starting point was a requirement for cleanliness class 10 and better (since 2001 - ISO 4).

For the first time, humans were largely ignored as a source of particles. Interface standards were defined, thus creating the basis for harmonising a wide variety of automation concepts. The first minienvironments were thus created.

Increased productivity was derived from the work flow optimised by automation.

The introduction of 300 mm technologies turned automation from an option into an obligation. Automation was always considered in combination with the necessary purity requirements. The question of a minienvironment was therefore inextricably linked to the automation of the processes.

What are the specifics of the semiconductor industry

Automation

On the one hand, the concept of automation has placed productivity and the reduction of human intervention at the centre of considerations. On the other hand, other problems arise. The influence of the operator with regard to the introduction of contamination is reduced. However, the integration of new sources of contamination, especially automation equipment, largely neutralises the aforementioned advantage and brings completely new aspects into the debate. These issues of cleanroom and cleanliness suitability are increasingly moving to the centre of the problem discussion. It has been established that the contamination generated by the process can also come from the process tool, the machine components, and therefore the entire equipment, both process and automation equipment, must be considered under this aspect.

Contamination due to the influence of the equipment used

New developments are increasingly demanding cleanroom and cleanliness-compliant machines and equipment. These in turn should consist of cleanroom and cleanliness-compliant components, individual parts and materials. This aspect is already important in the design phase. If the issues relating to the influence of the equipment on the product or process are not considered in good time during the concept phase, this leads to cost-intensive retrofits that are many times higher than the original expenditure required. The so-called rule of 10 states: omitted expenses at the beginning of a production chain, which are later necessary, in this case process purity, require 10 times the cost of the previous step with each subsequent step in the processing chain.

Purity requirements today

The purity classes from ISO 1 to ISO 9 for particle sizes up to 0.1 µm are described in ISO 14644-1. The ITRS (International Technology Roadmap for Semiconductors) roadmaps describe how the requirements for the various processes will steadily increase. Only the requirements for air purity are not evolving, as no air purity classes beyond ISO 1 have been defined.

The VDI is currently working on an extension and considering much smaller particle sizes. However, the classification cannot simply be extended ‘downwards’, as particles in the nanometre range behave differently in the air flow than particles ≥ 0.1 µm.

AMC (airborne molecular contamination, or ACC - airborne chemical contamination) already plays a very important role in the production of semiconductor elements, for example, and its significance will continue to increase significantly. In addition to questions about particles, this raises further questions about the materials used in the machines and components, their outgassing rates with regard to various elements and compounds and their influence on the product. It is possible to determine these parameters, but this creates a further cost factor in the conceptualisation and design process.

Suitable products/services for the semiconductor industry

The semiconductor industry places high demands on cleanliness. Cleanrooms usually have an air cleanliness class between ISO 5 and ISO 7. However, as these ISO classes are often not sufficient for the highly sensitive processes in the semiconductor industry, these processes are usually additionally protected from harmful particles with minienvironment solutions. This allows the largest source of particles - humans - to be almost completely excluded. In such a minienvironment, an air purity class of ISO 2 or even ISO 1 can be achieved.

In order to be able to ensure this particularly high level of purity required for the process, it is important to ensure that the materials are not only smooth and easy to clean when selecting them. They should also be resistant to solvents and low in outgassing. Anodised aluminium, glass and stainless steel are often used. You can find an overview of suitable materials here.

Minienvironment

On the one hand, you can achieve contamination-free production by using materials and machines that are suitable for cleanrooms and cleanliness. On the other hand, these parameters recede into the background if technical equipment - the minienvironments - is used to prevent these contaminants from entering the process and product area. If clean air is brought to the process location by an intelligent clean air flow and contamination is removed or shielded, there is no need to resort to cleanroom and cleanliness-compliant units.

With the start of the first 300 mm production in Dresden, SEMATECH and SEMI stipulated that every piece of equipment must have a minienvironment and that the equipment supplier is responsible for its function. This means that expertise in cleanliness issues is increasingly being assigned to the process. The companies concerned have the opportunity to build up the necessary knowledge or to bring external expertise into the team.

Adapted solutions, which have been used for a long time in retrofit fabs, are consistently avoided. Today, the minienvironment is an integral part of the production machine. The functional elements of the machine itself are linked with functional elements of the minienvironment. The purity-compliant design plays a major role here. Many different components are decisive for this. Only one of these, which must be taken into account, is the flow-optimised design.

Fulfilling cleanliness requirements - cleaning individual parts and assemblies

Many production devices for high-tech applications are still manufactured under ‘normal’ production conditions. The fact that final assembly alone takes place in a cleanroom is far from sufficient. The desired results of follow-up actions will not be achieved if the process chain is not considered in its entirety and consistently adhered to. This means, among other things, that final cleaning of the entire appliance is not possible efficiently if individual parts and components are neglected. This is because the contaminants, which may sooner or later emerge and damage the product, have been installed in places that cannot be subsequently cleaned as required by the cleanliness standards. Reference should be made to the ‘rule of 10’ mentioned above: If expenditure is not carried out at the beginning of a production chain, but is later necessary, in this case surface cleanliness, the cost of each subsequent step in the processing chain is 10 times higher than in the previous step.

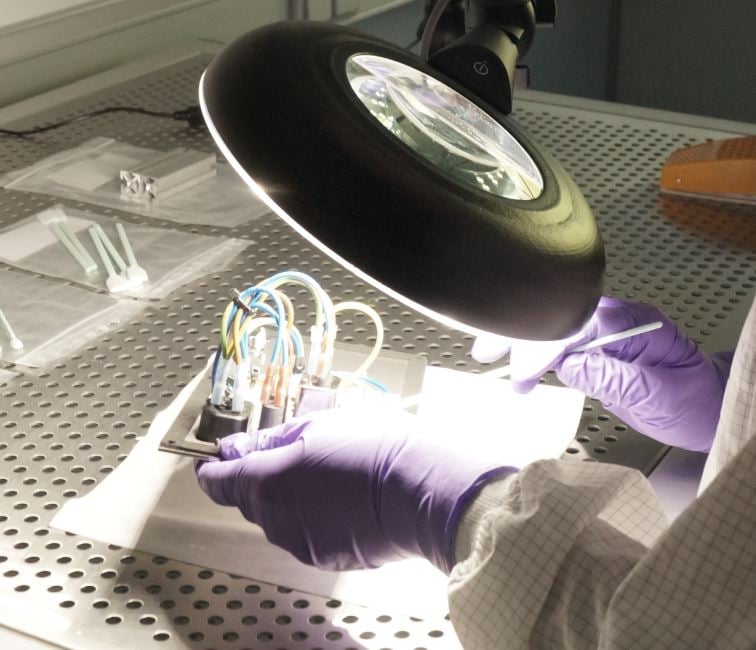

The following minimum requirements are necessary to maintain a process chain as far as possible:

- Knowledge of cleanroom-compatible design of devices and automation equipment

- Availability of cleanroom-compatible assemblies

- Cleanroom conditions for assembly

- Trained personnel for the production of devices

- Knowledge of cleaning parts, assemblies and devices

- Knowledge of cleanroom-compatible packaging and logistics

- Existing measuring equipment to monitor the work flow

COLANDIS as a partner for cleanroom requirements in the semiconductor industry:

The requirements for product purity are increasing in almost all areas, not just in the semiconductor industry. This is influenced by the following parameters:

- Human

- Process

- Equipment

- Process media

- Process environment/ cleanroom

The biggest cause of contamination and therefore also the biggest uncertainty factor for efficient and consistently high-quality production used to be people. In today's production, this is increasingly being replaced by automation solutions.

In order to provide the best possible protection for further process steps, we work with you to develop a suitable solution that is only as good as necessary and not as good as possible.

Cleanroom requirements and automation technology do not have to be antagonistic. If the basic rules for working and producing machines, devices and components are adhered to and the process chain is considered in its totality, a cleanliness-compliant production environment can be realised despite automation.

More interesting blog posts

2 min read

Clean environment in the machine – A story from experience

COLANDIS Marketing: Jan 13, 2025

2 min read

Reasons for regular cleanroom maintenance

COLANDIS Marketing: Jan 3, 2025