Optics industry

Cleanroom and cleanliness technology in optics and laser technology

According to the Duden dictionary, the term “optics” comes from the Greek and literally means ‘the science of seeing’. It mainly refers to the science of light, its creation, propagation and perception.

Hardly any other manufacturing process produces as many particles as the polishing of optics. However, it is not just a question of reducing the number of particles used for polishing, but rather of preventing the addition of foreign particles that do not originate from the polishing agent and that can cause micro-scratches during polishing and thus have a negative impact on quality.

What requirements are placed on cleanroom and cleanliness technology?

Air purity

In order to ensure high and consistent product quality, increasingly stringent requirements are being placed on purity in the optics and laser sector. Air purity plays a decisive role not only in terms of the number of particles, but also with regard to the composition of the particles. Molecular contamination is also becoming increasingly important.

Elektrostatic, EMC

All used components should be electrostatically dissipative in order to minimise the influence of discharge or electromagnetic effects. Appropriate components should be selected.

Laser protection

Additional laser protection may be necessary. At this point, it should be mentioned that laser protection films as room partitions do not offer 100 % protection against laser radiation. It cannot be guaranteed that these films completely separate laser areas from their surroundings. In addition, these films are difficult to clean due to their flexibility.

Scattered light effects

... should be avoided in order to be able to carry out processes under defined light sources. To achieve this, scattered light and reflections must be avoided. In optics production, quality inspection is often carried out under oblique light. Stray light must be prevented at all times.

Which alternatives are available?

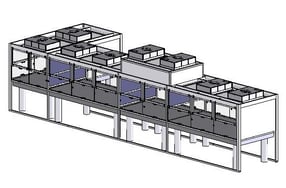

Minienvironments – an example

In a laboratory area, several interconnected optical tables needed to be equipped with an enclosure. An air purity class ISO 6, no connections to the optical table, foldable air baffles made of dissipative toughened safety glass for easy access and lighting without EMC interference had to be taken into account. All of this could be solved with a multi-part minienvironment.

Further advantages of a minienvironment can be found here

Laser application with a higher laser power

Two different things need to be considered for cleanliness solutions with a higher laser power:

- Laser protection must be comprehensive and seamless. This is realised with appropriate laser safety windows to ensure visibility into the process area, if this is necessary.

- Lasers are mostly used in combined optical systems. The surfaces of the optics are therefore exposed to high energy from the laser beam. In combination with the high laser power and the presence of hydrocarbons and other molecular compounds in the air, these are ‘cracked’ and then burn into the optical surfaces as carbon. This leads to increased regular cleaning requirements. With an appropriate air filter solution for these applications, the cycle between the individual necessary cleanings can be extended.

Black surface elements for better protection against ambient light

Any clean environment can be fitted with black surface elements. These offer optimum protection from external light and prevent reflections that can disrupt the process and its quality.

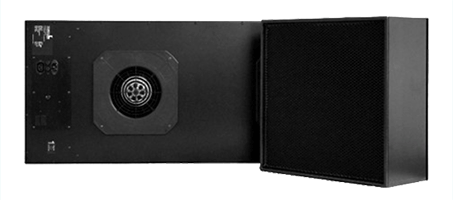

Fan-Filter-Module with black filter medium

Measurements are often carried out close to the filter medium in order to achieve the highest possible air purity. The problem with conventional white filters, however, is the brightness level, which is caused by scattered light and can massively disrupt and manipulate the measurement process. As an alternative, COLANDIS has developed a black fan-filter-module, which also has a black filter. With this completely black module, a reduction in reflection of more than 90 % can be achieved.

Measurements are often carried out close to the filter medium in order to achieve the highest possible air purity. The problem with conventional white filters, however, is the brightness level, which is caused by scattered light and can massively disrupt and manipulate the measurement process. As an alternative, COLANDIS has developed a black fan-filter-module, which also has a black filter. With this completely black module, a reduction in reflection of more than 90 % can be achieved.

COLANDIS as your partner for your clean environment

In optical and laser industries, production areas must not only be clean but also dark. Reflection and stray light effects must be prevented and eliminated. We are happy to support you in this and work with you to find the right solution for your process.

Other interesting blog post about this topic

2 min read

Fan-filter-module (FFU) with black filters

COLANDIS Marketing: Mar 6, 2025

2 min read

Reasons for regular cleanroom maintenance

COLANDIS Marketing: Jan 3, 2025