Measurement of equipment

Your proof that your products are suitable for cleanrooms

Do you need proof that your products, systems, assemblies or components meet the required airborne particulate cleanliness class? Do your customers want confirmation that your equipment can be used in a cleanroom, clean environment or workplace? Then you should have your products tested.

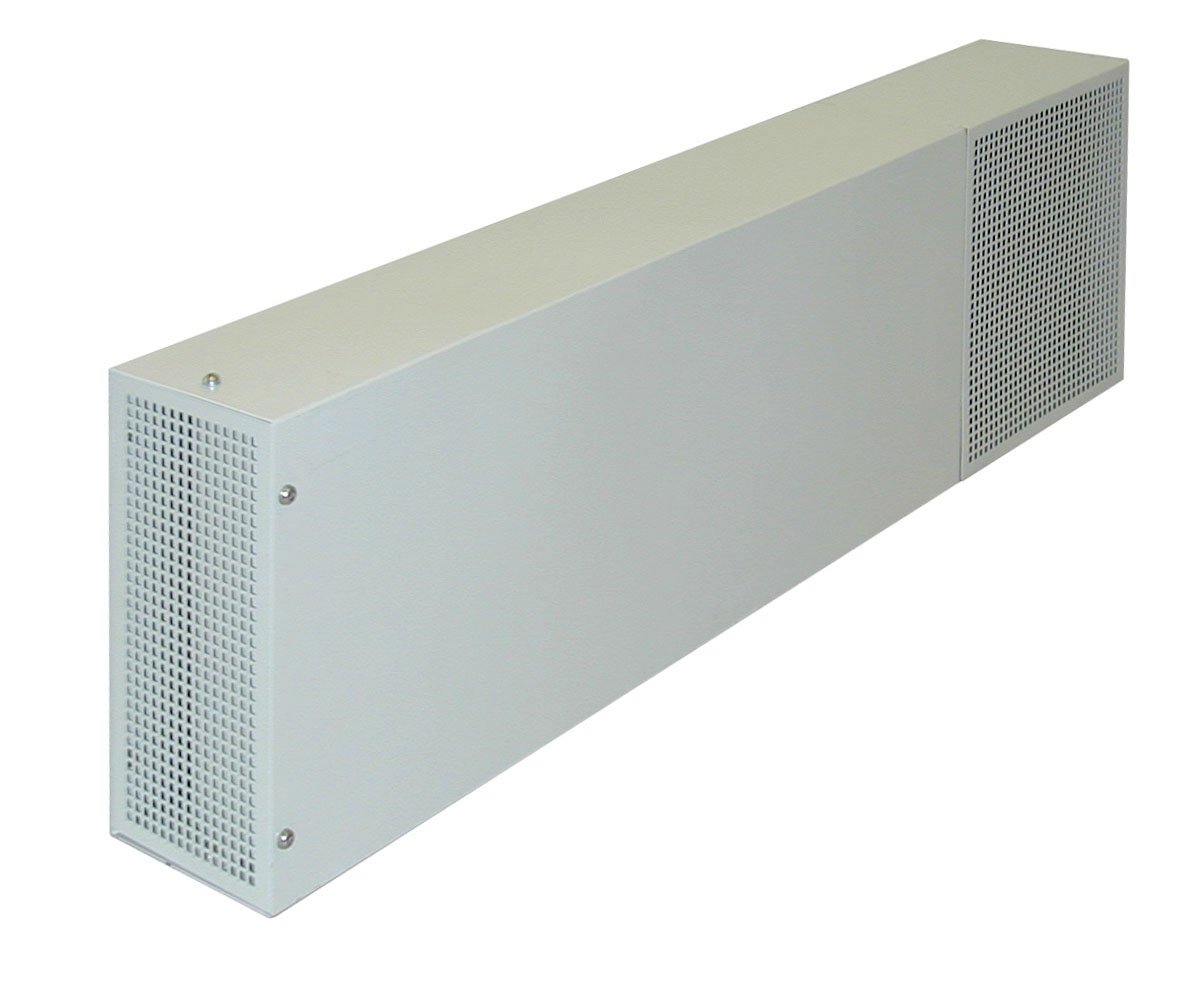

What is an equipment?

"Equipment includes, e.g. the facilities or objects listed hereafter, which are brought into a controlled environment.

This list of examples of pieces of equipment is based on the list given in VDI 2815 Part 5:

- Production facilities (such as bonders, assembly equipment, filling stations)

- Measuring and testing equipment (such as inspection, facilities, microscopes)

- Equipment for transport and handling (such as linear axles, conveyor belts, robots)

- Storage units (such as boxes, buffers)

- Organization tools (such as workpiece carriers)

- Interior furnishings (such as tables, chairs)

- Elements of interior work (such as walls, doors, ceilings, floors)

[source: VDI 2083; part 9.1 "Terms and definitons"; p. 8]

Cleanroom or cleanliness compatibility – What is measured?

The cleanliness compatibility! Because "compatibility with the required cleanliness serves to assess pieces of equipment or air-handling components in view of their use in cleanrooms. It describes the generation or existence of the contamination generated by, or existing on, the piece of equipment or air-handling component."

[source: VDI 2083 part 9.1 "Terms and defintions"; p.9]

Cleanroom compatibility, on the other hand, "serves to assess the suitability of a piece of equipment for use in cleanrooms specified in accordance with a technical rule for assessing the air cleanliness. For the purposes of this guideline, the classification is based on the particle emission."

[source: VDI 2083 part 9.1 "Terms and defintions"; p. 10]

Cleanroom suitability tests of these products essentially assesses the influence on the production environment. These can thus be assessed with regard to their use in the clean environment with a defined airborne particulate cleanliness class.

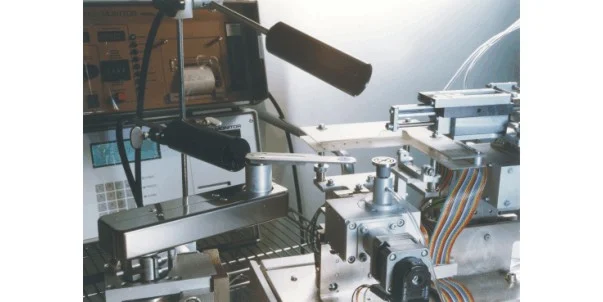

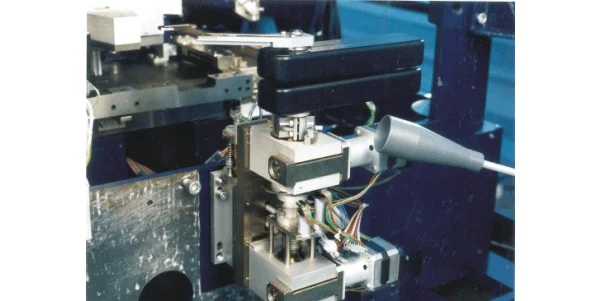

The result of the investigations is a transparency and comparability of the purity properties of operating and production equipment. The places where most contaminations are suspected are scanned. This is followed by a representative grouping of all measured points of measurement. After the evaluation of these measuring points, the worst measuring point is revealed. This is then used for a 100 minute measurement to classify the component. The results confirm whether the product can be used in a clean environment without worsening ist results.

.png?width=80&height=80&name=like%20(1).png)

Advantages

- Independent proof of the cleanliness suitability of your operating resources for your customers in accordance with DIN EN ISO 14644-14

- Ability to provide your customers with data for their cleanroom planning

- Measuring range of all cleanliness classes in our ISO 1 cleanrooms

- Possibility of a series test

- COLANDIS seal of approval

- TÜV-certificate possible

- Improved market opportunities compared to competitors

- Introduction of operating resources of different sizes possible

- Support in the targeted selection of suitable operating resources and components to help ensure your desired product quality

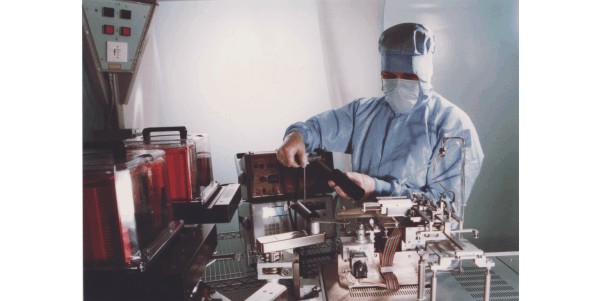

Functionality

The product/system is delivered, unpacked and subjected to a visual inspection (identification of possible particle sources, air flow resistance and inspection of the overall structure). Depending on the complexity, we assemble these products together with our customers. The ‘actual’ condition is then documented and recorded. This is followed by step-by-step cleaning before the product is transferred to the ISO Class 1 cleanroom. The final assembly then takes place so that the product can run in regular operating mode. After configuration, cleaning is carried out again to rule out any foreign contamination. Only now does particle detection take place.

Following planning and preparation, the measurements are carried out. These include:

- Measurement of environmental conditions at the time of the investigation: temperature, humidity, air flow velocity and cleanroom class at the installation site are measured

- Checking the air cleanliness class on the equipment: scanning using an optical particle counter, determining the measuring points and performing the classification measurement

- Documentation with a statistical evaluation of the measurement results and a summary

- Suggestions for optimisation if the required ISO class is not achieved

- Working together to find solutions that optimise the cleanliness suitability of your operating resources

Best solution for your process

Your product will receive the ‘cleanroom tested’ rating. An additional COLANDIS certificate can be issued as an option, or by TÜV SÜD on request.

This certificate confirms that your materials, components, machines and equipment meet certain technical requirements and can be used in a specified environment. On the certificate you can see which particulate cleanliness class of the air is achieved in the various areas and in which operating condition this ISO class was achieved. Furthermore you can see the suggested interval for the next maintenance.

As COLANDIS is a completely independent company and is not subordinate to any other company or organisation, we guarantee complete independence with regard to our measurement services.

Applications

Based on our measurement results, the test item is classified with an air cleanliness class in accordance with the guidelines DIN EN ISO 14644-1 and 14644-14. A report is issued to you based on this classification.

Frequently asked questions

-

Which area can be measured?

All cleanliness classes can be measured in our ISO 1 cleanrooms.

-

How large can the operating equipment be?

Operating materials measuring up to 2 x 3 x 2.5 m³ (L x W x H) can be brought in.

-

Which certificate do I receive?

Based on the classification, you will receive a COLANDIS protocol. Your product will be awarded the ‘cleanroom tested’ label. An additional COLANDIS certificate can be issued as an option, also from TÜV SÜD on request.

Weitere Produkte und Services»

Nutzen Sie die Möglichkeiten unserer Netzwerke!

- Minienvironment