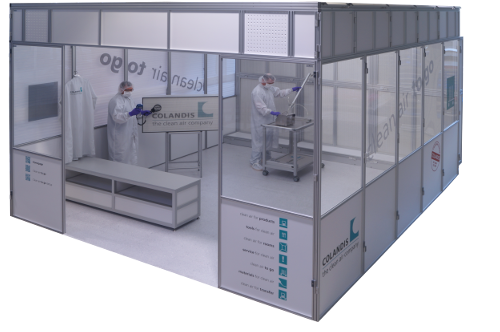

Measurements of cleanrooms and clean environments

Cleanroom testing and qualifications

Measurements and qualifications in cleanrooms and clean environments serve to prove the airborne particulate cleanliness class. This verification is carried out, for example, after installation and maintenance, but also at regular intervals during operation of a clean environment. This helps to prevent quality losses due to particle contamination, as changes in cleanroom and cleanliness technology, production processes or altered, incorrect behaviour by employees in the clean environment have a significant impact on air quality.

.png?width=80&height=80&name=like%20(1).png)

Advantages

The (re)qualifications assess the quality of the room. Airborne particles are counted based on these cleanroom measurements. Subsequently, a particulate cleanliness class according to DIN EN ISO 14644 can be determined based on these results.

Functionality

Measurements in a cleanroom or clean environment:

- Visual inspection of the room and optical inspection of the filters and pre-filters. In addition, preliminary tests are carried out, such as checking the air volume flow and air velocity, determining the air exchange rate, checking the differential pressure and the tightness of the filters.

- The airborne particles are then counted at full operating capacity. Particle sizes ranging from 0.1 µm to 10.0 µm can be measured.

- The particulate cleanliness class of the air is determined in accordance with DIN EN ISO 14644-1 on the basis of statistical evaluation and logging of these measurements. The results are compiled in a test report.

- Additionally, climate parameters (temperature/relative humidity) can be recorded, sound pressure level measurements can be performed, recovery times can be recorded, and the number of germs in the air and on surfaces can be determined. Further safety qualifications, such as ESD measurements in the room and on various components, are also possible.

Best solution for your processes

You should also have your cleanroom (re)qualified regularly to ensure that it meets the required air cleanliness class. It gives you the assurance that you are complying with the required parameters and protecting your products and processes in accordance with the requirements for contamination, impurities and environmental influences, such as particles.

COLANDIS as your partner offers you:

- Tests and measurements in accordance with prescribed standards as per VDI 2083 Sheet 3 and Sheet 9.1 as well as DIN EN ISO 14644-1 and 14644-3

- Results collected using currently calibrated and certified measuring equipment

- Measurements in various operating states of the cleanroom (provision, idle, production)

- Cyclical inspections for the requalification of cleanrooms in accordance with agreements and/or service contracts

Get in touch with us. We will be happy to help you assess your clean environment. As a result, you will receive a detailed report with a graphical representation of all results.

Applications

A measurement can and should be carried out in every cleanroom. It enables you to provide certified proof to your customers.